In the ever-growing pet food industry, packaging plays a pivotal role in preserving product quality, ensuring convenience, and meeting regulatory standards. Whether you’re producing dry kibble, gourmet wet food, or delicious treats, selecting the right packaging machine is crucial for maintaining efficiency, protecting the product, and meeting consumer demands.

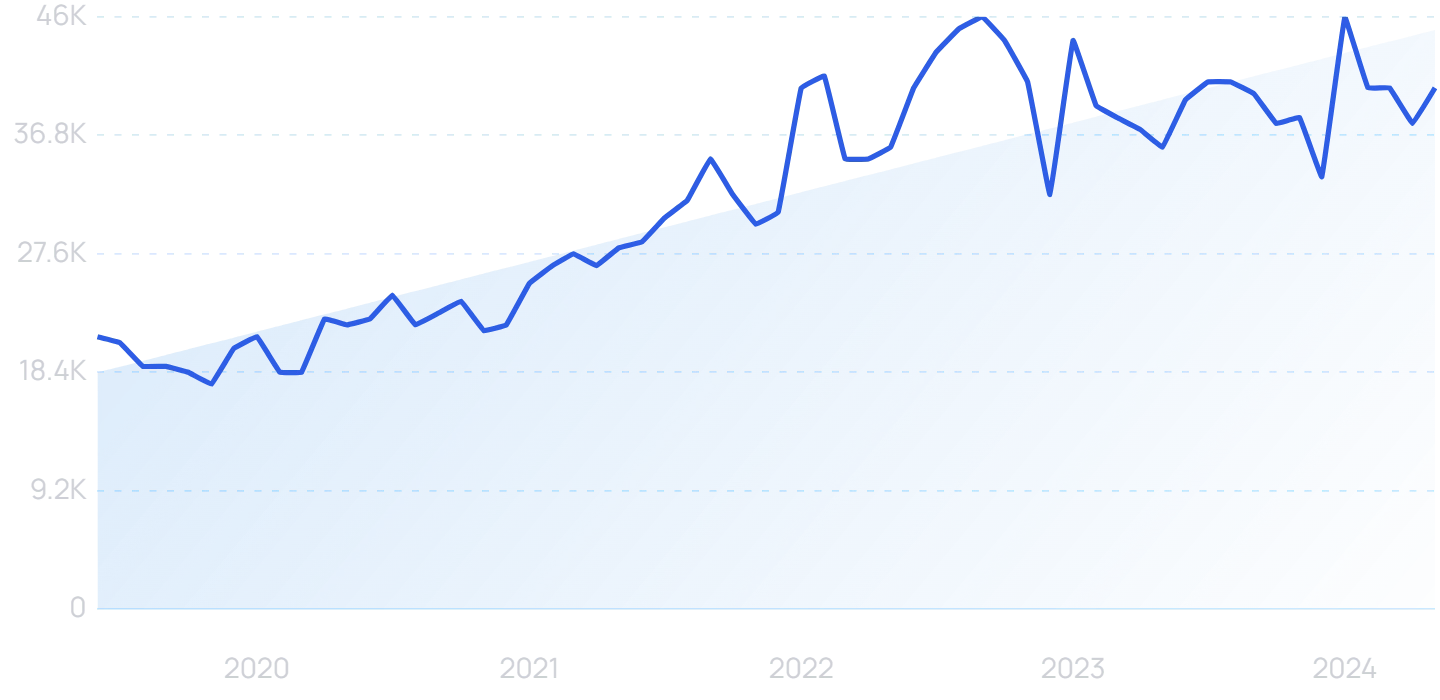

Google searches for “raw dog food” are up 216% over 10 years.

With the variety of machines available today, choosing the best one can be daunting for pet food manufacturers. A wrong decision can lead to increased costs, production delays, and potential quality issues. That’s why understanding the key factors that contribute to selecting the ideal packaging machine is essential for optimizing your production line.

In this article, we’ve compiled 10 expert tips to guide you through the process of choosing the most suitable packaging machine for your pet food products. From evaluating your product needs to factoring in long-term costs, these tips will help you make an informed decision that aligns with both your immediate and future goals.

1. Understand Your Product Needs

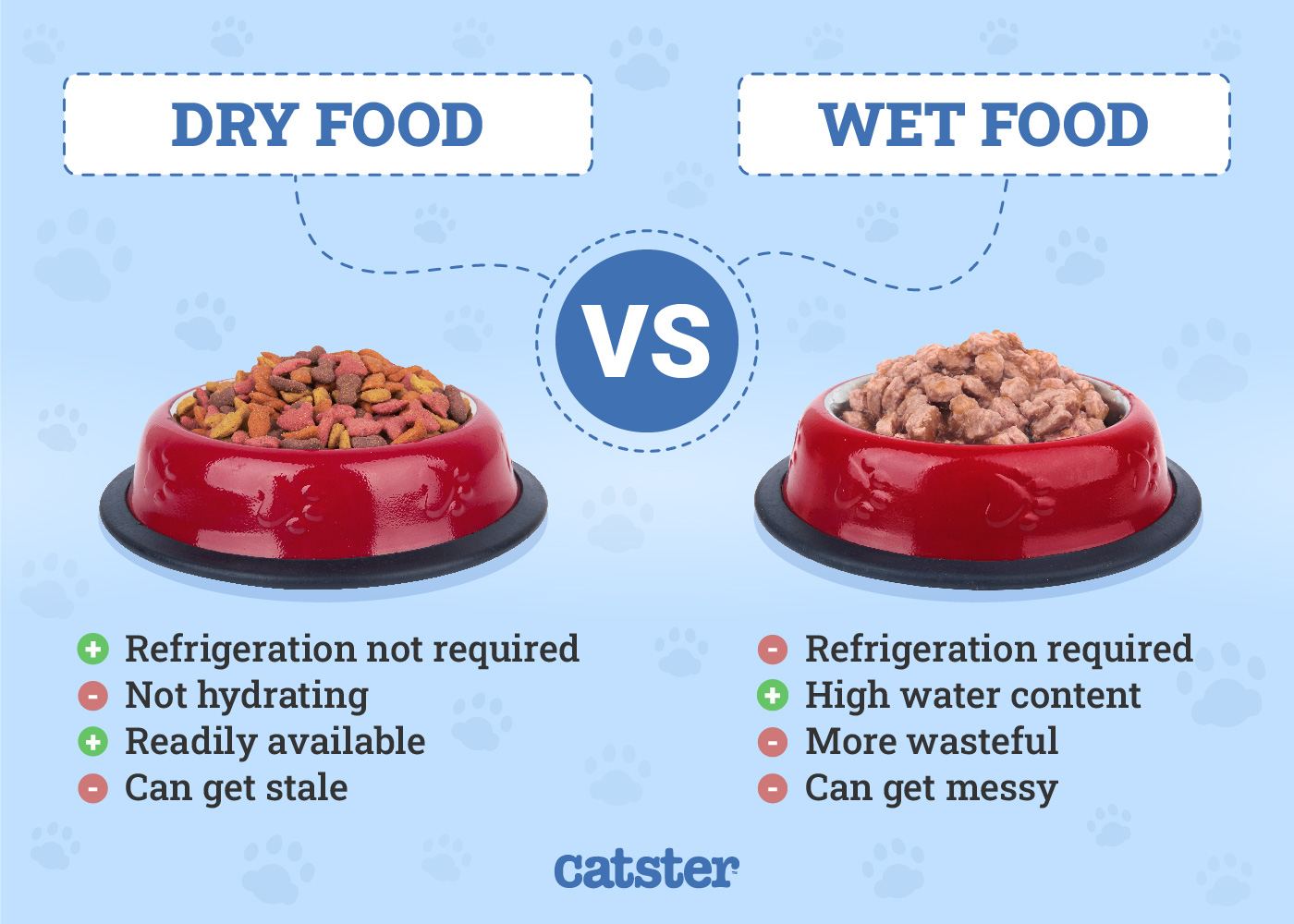

Tip: Assess the type of pet food you’re packaging (dry, wet, treats) to determine the most suitable packaging machine type.

- Dry vs. Wet:Wet pet food requires packaging that prevents moisture loss, contamination, and spoilage. It might need vacuum sealing or cans. Dry food, on the other hand, often needs moisture barriers and robust seals to maintain freshness.

- Treats: Pet treats often need flexible packaging that can easily be resealed to preserve freshness and prevent odor leakage.

- Supplements and Medicines: These often require tamper-proof, child-resistant, or secure packaging to ensure safety.

2. Evaluate Machine Speed and Efficiency

Tip: Match the machine’s speed with your production demands to ensure efficiency and avoid bottlenecks.

- Machine Speed (Throughput)

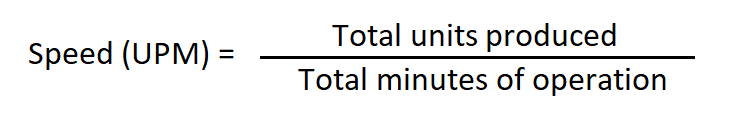

Units per Minute (UPM): This is a direct measure of how many units (bags, cans, pouches, etc.) the machine can pack per minute. It’s essential to know your production volume to match it with the machine’s speed.

Formula:

Max Speed vs. Optimal Speed: Always consider both the machine’s maximum speed and the speed at which it operates most efficiently under normal working conditions. Running a machine at its maximum speed constantly might reduce its longevity and increase maintenance costs.

Speed Scaling with Product Variability: The speed can decrease when switching between different product sizes, types, or materials. Machines should have a flexible speed range depending on product changes.

- Efficiency Metrics

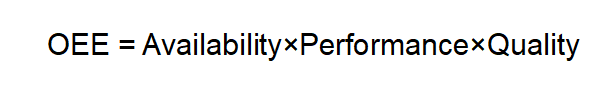

Overall Equipment Effectiveness (OEE): OEE is a comprehensive metric that combines three key factors: Availability, Performance, and Quality.

Availability: This measures machine uptime vs. downtime (e.g., maintenance, changeovers).

Performance:This checks if the machine is performing at its intended operational velocity.

Quality: This checks for the number of defective products produced.

Formula:

A good target OEE score is typically around 90% or higher, but this can vary by industry.

Downtime: Track both planned (e.g., maintenance) and unplanned (e.g., machine failure) downtime. Minimizing downtime can significantly improve efficiency.

Planned downtime: Scheduled maintenance, cleaning, or product changeover.

Unplanned downtime: Breakdowns or errors that stop production unexpectedly.

Changeover Time: The time what we need to spend for change product specification. In the pet food industry, you might be switching between different types of packaging or different flavors of pet food. Machines with quick-change features or automated changeover systems are more efficient in minimizing this downtime.10 tips to choose a suitable packaging machine for packaging pet food.

3. Package format

Tip: Choose a machine that can handle multiple packaging formats (pouches, bags, trays, etc.) for future flexibility.

- Flexible Pouches(Stand-up Pouches, Flat Bottom Bags, Pillow Bags, Four-Sided

Sealed Pouch, etc.

Common for: Dry food, treats, and wet food.

Features: Lightweight, space-efficient, resealable, and often equipped with tear notches or spouts.

Benefits: They’re easy to store, keep food fresh with high-barrier materials, and can include features like transparent windows for consumers to see the product.

- Cans

Common for: Wet pet food (e.g., dog and cat food).

Features: Traditional option, sealed to prevent spoilage.

Benefits: Long shelf life, good protection from external elements, and offers a premium, recognizable look. However, they are less environmentally friendly compared to other formats.

- Plastic Containers

Common for: Dry and semi-moist pet food.

Features: Rigid, stackable, and often come with screw-on lids or snap-on closures.

Benefits: Good for bulk food, protects against moisture and contamination, and is highly durable. However, they can be bulky and less eco-friendly.

- Cardboard Boxes

Common for: Dry food (often kibble or biscuits).

Features: Made from recycled paperboard, often with a protective inner liner.

Benefits: A sustainable option, easy to stack, and allows for more colorful branding. However, it’s not as durable against moisture as plastic or metal packaging.

- Tetra Paks

Common for: Wet food, especially liquid or gravy-based pet food.

Features: Sealed and multi-layered cartons for longer shelf life.

Benefits: Lightweight, easy to store, and made from renewable sources, making it more eco-friendly. Tetra Paks also offer excellent protection from light and air, preserving product quality.

4. Look for Precision and Consistency

- Weight/Volume Measurement

Precision Test: Weigh a sample of filled packages at various points during the production run. Measure how each sample’s weight aligns with the established target weight. A precise machine should deliver very similar weights for each package within the tolerance limits. You can also consider adding the check weigher after the packing machine.

5. Consider Packaging Materials Compatibility

Tip: Choose a machine that can work with a range of packaging materials (films, foils, laminates) based on product type and shelf-life needs.

Moisture & Air Resistance: Choose materials that offer strong barriers against moisture, oxygen, and light (such as laminated films or foil-based materials).

UV Protection: Using opaque materials or UV-resistant coatings can help preserve the nutritional value.

- Material Durability

Tear and Puncture Resistance: Pet food packaging should be strong enough to withstand rough handling, storage, and transportation. This is especially important for dry kibble, which can cause packaging to tear if not properly designed.

Impact Resistance: Consider how the packaging will perform if dropped or bumped during handling. Materials like polyethylene or polypropylene can offer more resistance to impacts.

- Food Safety

Non-toxic Materials: Packaging should be made from food-grade materials that are safe for both pets and humans. Look for certifications like FDA approval or compliance with food safety regulations.

No Chemical Migration: Make sure the material is suitable for pet food and free from harmful substances that could pose health risks.

- Sealing & Closure Systems

Seal Strength: A reliable heat-seal or pressure-seal is essential to protect the freshness of pet food and prevent leaks or contamination.

Resealability: Consider whether the packaging needs to be resealable (e.g., for bags of dry food). Zipper closures or fold-over seals can provide convenience for consumers and help maintain product freshness after opening.

- Environmental Impact

Sustainability: Choose packaging materials that are recyclable, biodegradable, or made from recycled materials. This can appeal to environmentally-conscious consumers and help reduce waste.

Lightweight Design: Minimizing the weight of packaging can reduce transportation costs and improve overall sustainability.

- Regulatory Compliance

Labeling: Ensure the material can be printed on and will not degrade or distort labels, ensuring clear communication of nutritional info and other product details. We can provide the labeling machine for your choice.

- Compatibility with Packaging Machinery

Machine Compatibility: Choose materials that can easily be processed by the packing machinery without causing jams, tears, or excessive waste. Make sure the material is available in the appropriate size and format for your machinery.

- Consumer Convenience

Easy to Open: Packaging should be easy for pet owners to open and close, especially for larger bags of pet food. Easy-pour spouts, perforated openings, or tear-notch designs can enhance convenience.

Attractive Appearance: Pet food packaging needs to be visually appealing to consumers. The material should allow for vibrant printing, so it stands out on the shelf while conveying the brand’s message.

6. Factor in Space and Layout Requirements

Tip: Ensure the machine fits within your facility’s space constraints and works with your existing production layout.

Available Space in the Factory (Physical Footprint, Height Considerations)

Workflow and Production Line Integration (Connection to Existing Systems, Flow Efficiency, Ergonomics)

Machine Accessibility and Maintenance Space (Ease of Maintenance, Training

Environmental and Safety Considerations (Safety Compliance, Ventilation, and Cleanliness)

Energy and Utility Requirements (Power Supply, Compressed Air, and Water)

Integration with Packaging Materials (Material Storage and Supply)

7. Account for Automation and Integration

Tip: Choose machines with automation features that integrate easily with other parts of your production line for smooth operations.

8. Assess After-Sales Support and Warranty

Tip: Select a supplier who offers strong after-sales support, including installation, training, and ongoing maintenance.

9. Calculate Total Cost of Ownership

Tip: Don’t just focus on the upfront cost; factor in long-term operational costs like maintenance, energy usage, and downtime.

By considering these tips, pet food manufacturers can select a packaging machine that not only protects the product but also enhances production efficiency and aligns with consumer expectations. With the right equipment, you can meet the demands of the pet food market, maintain a high level of quality control, and ensure a positive customer experience, ultimately leading to greater success in the industry.